Sulfamic Acid Crystal for Sale

- Synonyms: Sulphamic acid

- CAS No: 5329-14-6

- HS Code: 2811199090

- MF: H2NSO3H/H3NS03

- Purity ,(%): ≥99

- Appearance: white crystalline powder

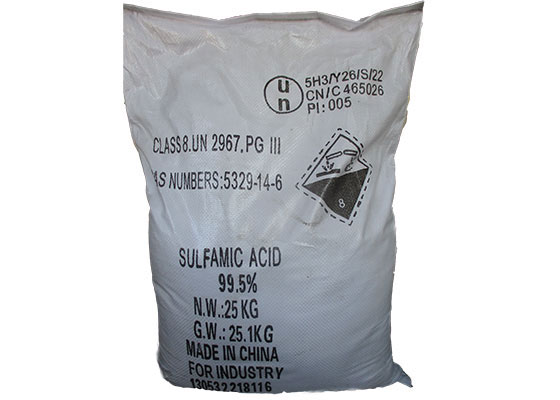

- Package: Plastic woven sack with inner polythene film, N.W:25kg. G.W:25.1kg. 27MT/20’FCL, if on pallets 25MT/20’FCL.

Technical Specification of Sulphamic Acid for Sale in Fengbai

| Item | Standard (HG/T2527-2011) |

| Purity % | ≥99 |

| Sulphate % | ≤0.2 |

| Fe, ppm | ≤50 |

| Water insoluble substance % | ≤0.05 |

| Loss on Drying | ≤0.1 |

| Heavy metal (Pb), ppm | ≤10 |

Inquiry Us for Quotation Here

Leave your requirements in detail here(including the specifications, package, quantity, country, etc.), we will reply you quickly.

SEND US EMAILGET PRICE NOWWhat is sulfamic acid used for

Widely used in a variety of industrial equipment and civil cleaning agents for metal and ceramic manufacturing, electroplating industrial gents, electrochemical polishing agents, asphalt emulsifiers, etchants, dyes. Used as sulfonating agent, dyeing agent, high-efficiency bleaching agent for dyestuff medicine and pigment industry. Used as flame retardant, softener, resin cross-linking accelerator for fiber and paper, herbicide, anti-blight agents, standard analytical reagents, etc.

Main Uses of Sulfamic Acid Cleaner

As a cleaning agent, sulphamic acid and its salts and various metal compounds can generate soluble salts, which have the characteristics of high degree of dissolution in water without precipitation and little corrosion to metals. So it is widely used.

Sulfamic acid aqueous solution can remove rust, scale and corrosion products on the surface of equipment made of iron, steel, copper, stainless steel and other materials. However, it has a slow effect on the corrosion products of iron, so some additives can be appropriately added to effectively dissolve the iron scale.

Used as an acid cleaner, it is an alternative to hydrochloric acid for rust removal. In households it is often used as a descaling agent in detergent, cleaners and toilet cleaners to remove limescale.

For cleaning boilers, condensers, heat exchanges, jackets and chemical pipelines.

It is used in breweries to remove scale from glass-lined storage tanks, pots, beer coolers, and beer keg.

Clean evaporators in enamel plants, and equipment in paper mills, etc.

In terms of air conditioning, it can remove rust and scale from cooling systems and evaporative condensers.

It can be used to clean limescale from copper pots, radiators, dishwashing mechanisms, silverware, ceramic tiles, food and milk processing equipment.

Used to remove protein deposits on digesters and deposits on sterilized aluminum used in fresh meat, vegetable, and cheese processing plants.

In paper and pulp industry

Sulphamic acid can inhibit pulp degradation due to the temperature of the hydrochloride and chlorination stages. It allows bleaching at elevated temperatures and lower PH without any loss of strength.

In dyestuff and pigment industry

Sulphamic acid can remove excess nitrides used in diazotization reaction during dye and pigment manufacturing. If nitrogen compounds are present in the wastewater, they can also be removed by using sulfamic acid.

Chlorine in water forms HOCL. It reacts with sulphamic acid to form more stable N-chlorosulfamic acid, which has active chlorine. Therefore, sulfamic acid is used for chlorine stabilization in swimming pools and cooling towers.

In Oil Industry

Sulfamic acid can be used to unblock the oil layer and improve the permeability of the oil layer. Inject sulphamic acid solution into the carbonate reservoir. Because sulfamic acid easily reacts with oil reservoir rocks, it can avoid the deposition of salts generated by the reaction.

In Agriculture

Sulfamic acid and ammonium sulfamate were originally developed as herbicides.

Electroplating Solution

In the new aqueous gold plating solution, alkali metal sulfamic acid can be used as a compound for conducting and buffering.

Frequent Asked Questions About Sulfamic Acid H3NSO3

Sulfamic acid, with chemical formula of H3NS03, is a kind of inorganic solid acid formed by replacing the hydroxyl group of sulfuric acid with amino group. It is generally white, odorless rhombohedral flaky crystals in appearance. The aqueous solution of sulfamic acid has the same strong acidity as hydrochloric acid and sulfuric acid, so it is also called solid sulfuric acid. Sulphamic acid can be used to synthesize herbicides, fire retardants, sweeteners, preservatives, metal cleaning agents, etc. It is a common chemical raw material.

The molecular weight is 97.09, relative density is 2.126, melting point is 205℃.

Soluble in formamide and water, slightly soluble in concentrated sulfuric acid, methanol, acetone and ether.

At room temperature, as long as it is kept dry and not in contact with water, solid sulfamic acid does not absorb moisture and is relatively stable.

It has the characteristics of non-volatile, odorless and low toxicity to human body.

Dust or solution is irritating to eyes and skin. It can cause burns, the maximum allowable concentration is 10mg/m³.

Sulfamic acid melts at 205 °C and then decomposes to water, sulfur trioxide, sulfur dioxide and nitrogen at higher temperatures.

There are two main methods for the production of sulphamic acid. One is gas phase method using sulfur trioxide and ammonia as raw materials, and the other is liquid phase method using urea and oleum as raw materials.

Gas Phase Method

Production process. The gaseous sulfur trioxide and ammonia gas are directly reacted to generate ammonium sulfamate. Then add water to neutralize sulfuric acid for hydrolysis to produce sulphamic acid and ammonium sulfate. Precipitate the sulfamic acid from mother liquor, then separate, purify and dry to get sulfamic acid crystal.

Advantages. No waste acid is produced, the raw materials can be recycled, and the utilization rate is high. However, the conversion rate is low, the corrosion of equipment is heavy, and a large amount of by-product sulfuric acid will be produced in production.

Liquid Phase Method

Production process. Subject the urea and oleum to sulfonation reaction at 40-70℃ to generate crude sulfamic acid. The treat the crystallization with water to obtain fine sulphamic acid.

Advantages. Under normal pressure, the amount of waste acid produced is small, the waste gas is mainly CO2, and the impact on the environment is small.

For removing excess grout from tiles or dissolving weathering on walls, floors, etc. The sulfamic acid solution is prepared by dissolving 80-100 grams per warm water. Apply to the surface with a cloth or brush and let it work for a few minutes, Stir with a brush and rinse with clean water if necessary. Note: If using around colored grout, use a weaker solution of 2% to reduce the risk of leaching any color from the grout.

For descaling equipment. Please use 10% solution. Sulfamic acid is safe for steel, iron, glass and wood equipment. Caution is required when used on copper, aluminum and galvanized metal surfaces.

For boiler systems and cooling towers, use 10% – 15% solution for circulation treatment, depending on the severity of the system. Note: Don’t use at boiling point, otherwise the product will hydrolyze and not work.

Low toxicity. It has a certain irritating effect on the skin and eyes. Production equipment should be airtight, and operators should wear protective gear.

Where to Buy Sulfamic Acid

Buy sulphamic acid from Fengbai – a reliable supplier with more than 15 years export experience in China. We can guarantee the best sulfamic acid price. Feel free to inquiry us now.